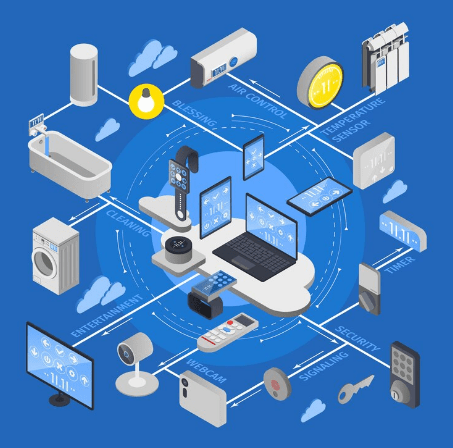

IoT Use Case for Compressed Air Flow Monitoring

Compressed air flow monitoring is a critical aspect of industrial operations, as compressed air systems are widely used in manufacturing processes, pneumatic tools and equipment. Monitoring compressed air flow helps ensure system efficiency, detect leaks, optimize energy usage and reduce operational costs.

Here's how an IoT solution for compressed air flow monitoring could be implemented:

Sensor / IoT Deployment

Install IoT devices equipped with air flow sensors or meters at key points along the compressed air distribution network, including compressors, pipelines, storage tanks, distribution lines and end-use equipment. These sensors combined with IoT controllers measure parameters such as flow rate, pressure, temperature and humidity.

Real-Time Monitoring

The deployed IoT controllers connected with sensors continuously monitor compressed air flow conditions and collect real-time data on flow rates, pressure drops and system performance. Data is transmitted wirelessly to the cloud server, web and mobile applications will be provided for the users to witness the real time data and its reports.

Data Analysis and Visualization

Upon receiving the sensor data, the IoT platform processes and analyzes the data in real-time. Data analytics algorithms may be applied to detect anomalies, identify inefficiencies and assess the overall performance of the compressed air system. Visualizations such as charts, graphs and heatmaps provide insights into flow patterns, usage trends and energy consumption.

Leak Detection and Energy Optimization

Analyze compressed air flow data to detect leaks, inefficiencies or excessive energy consumption in the system. IoT algorithms can identify abnormal flow patterns or pressure drops indicative of leaks or system malfunctions. By promptly detecting and repairing leaks, organizations can reduce wasted energy, lower operating costs and improve system reliability.

Predictive Maintenance

Apply predictive maintenance techniques to compressed air systems based on IoT data analysis. Predictive analytics algorithms can identify potential equipment failures or performance degradation before they occur. By monitoring factors such as flow rates, pressure fluctuations and equipment vibration, organizations can schedule maintenance proactively, minimize downtime and optimize equipment lifespan.

Energy Efficiency Optimization

Optimize the energy efficiency of compressed air systems by analyzing flow data and adjusting system parameters in real-time. IoT solutions can optimize compressor operations, control air pressure levels and adjust air supply based on demand. Variable frequency drives (VFDs) and energy management algorithms help minimize energy consumption and reduce operating costs.

Remote Monitoring and Control

Enable remote monitoring and control of compressed air systems through IoT-enabled interfaces or mobile applications. Facility managers and maintenance personnel can access real-time flow data, receive alerts, adjust system settings and perform diagnostics and troubleshooting remotely. Remote monitoring capabilities improve system visibility, enable faster response to issues and enhance operational efficiency.

Integration with Maintenance Management Systems

Integrate IoT flow monitoring data with computerized maintenance management systems (CMMS) or enterprise asset management (EAM) software. Streamline maintenance workflows, track equipment performance and generate maintenance schedules based on real-time flow data and predictive analytics insights. Integration with ERP systems facilitates cost tracking, budgeting, and financial reporting for compressed air system maintenance and operations.

Contact Info

-

Location: Plano, TX 75024, US.

-

Email: info@ktgsoftware.com