Sample Use Case of IoT Gateway for Communicating with PLC

In an industrial setting, particularly in manufacturing plants or production facilities, the integration of IoT (Internet of Things) technology with Programmable Logic Controllers (PLCs) can significantly enhance automation, monitoring and control capabilities. Here is a sample use case of an IoT gateway for communicating with PLCs:

Scenario

A manufacturing global company that operates a large-scale production facility wants to improve their operational efficiency, reduce downtime and gain real-time insights into their manufacturing processes. To achieve this, they decide to implement an IoT gateway to connect their PLCs with their enterprise-level systems.

Solution

Components

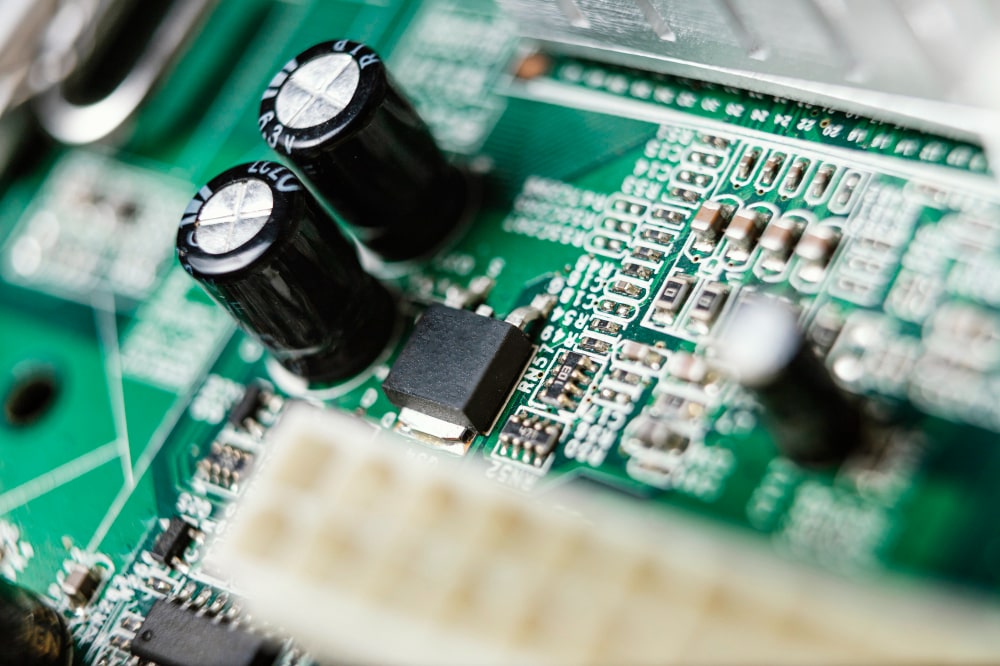

PLCs, Programmable Logic Controllers are used to control various industrial processes, such as machinery operation, assembly lines, and production workflows. An IoT gateway serves as a bridge between the PLCs and the cloud or enterprise-level systems. It collects data from PLCs, preprocesses it and transmits it to the cloud for further analysis and visualization. Various sensors are installed throughout the manufacturing facility to collect data on parameters such as temperature, pressure, humidity, vibration and machine status. The IoT gateway communicates with cloud platforms or enterprise-level systems, where data is stored, analyzed and visualized. This allows for remote monitoring, analytics and control of manufacturing processes.

Workflow

The IoT gateway collects data from PLCs and sensors installed on machinery and equipment. This data includes operational parameters, machine status, production counts and other relevant metrics. It preprocesses the collected data, performing tasks such as data filtering, aggregation, and transformation. This ensures that only relevant and meaningful data is transmitted to the cloud or enterprise systems, optimizing bandwidth usage and reducing latency. The processed data is transmitted securely from the IoT gateway to the cloud or enterprise systems using communication protocols such as MQTT (Message Queuing Telemetry Transport) or HTTPS (Hypertext Transfer Protocol Secure). In the cloud or enterprise systems, the transmitted data is stored for further analysis. Advanced analytics techniques, such as machine learning algorithms, can be applied to the data to identify patterns, anomalies and optimization opportunities. Real-time dashboards and visualization tools are used to monitor manufacturing processes remotely. Key performance indicators (KPIs), alerts, and notifications are displayed to operators and management, enabling proactive decision-making and timely interventions.

Benefits

The integration of IoT with PLCs provides real-time visibility into manufacturing processes, allowing for better control and optimization of operations. By analyzing data collected from PLCs and sensors, predictive maintenance algorithms can identify potential equipment failures before they occur, minimizing downtime and reducing maintenance costs. IoT-enabled automation and optimization lead to increased production efficiency, reduced waste and improved overall productivity. Access to real-time and historical data enables data-driven decision-making, allowing organizations to identify trends, optimize processes and drive continuous improvement initiatives.

Contact Info

-

Location: Plano, TX 75024, US.

-

Email: info@ktgsoftware.com